For 50 years, N.J. McCutchen has grown into one of the largest industrial metal fabricators with an unwavering dedication to providing quality solutions. From high-pressure tanks and industrial-scale food processing equipment to mobile utility power trailers, we have developed many products across a range of industries and applications. Today, we serve customers throughout the Central…

Sustainable Practices for Chemical Tank Management

Materials that pose a risk to human or environmental health fall under the category of hazardous waste, which can also comprise inherently dangerous materials. Examples of these materials include toxic substances, harmful chemicals, radioactive materials, and other types of potential pollutants requiring safe disposal and handling. When determining how to safely and properly store and…

Best Practices for Machining Operations in Stockton

Safety and efficiency across machining operations are more important than ever. Setting best practices helps machinists more effectively leverage existing resources and meet precise design requirements. At N.J. McCutchen, we strive to help our clients maintain strong operations, product quality, and business security. That’s part of why we continue to refine our machining services in…

Choosing the Right Surface Preparation in Stockton: Sandblasting vs. Other Methods for Industrial Coatings

Before a metal component can be painted or powder coated, its surface must be free from dirt, oil, rust, and other contaminants that interfere with good adhesion. Sandblasting is a common choice, but there are many additional options available. Here, we’ll compare sandblasting with soda blasting, wet blasting, and vacuum blasting. We’ll also look at…

Understanding ASME Code Work

Companies that design, fabricate, and operate pressure vessels and related equipment need to understand ASME code work. The American Society of Mechanical Engineers (ASME) established this group of comprehensive codes and standards to ensure these processes happen safely, reliably, and efficiently. The ASME Boiler and Pressure Vessel Code (BPVC) was established in 1911. It remains…

Welding Wonders in Stockton: Where Quality Meets Expertise

In construction and manufacturing, welding is indispensable for creating strong, durable structures and products. Within this domain, Stockton is renowned for its expertise in welding, where skilled professionals merge innovation with precision craftsmanship. The city, as a hub of welding excellence, underscores the vital role of welding in shaping various industries. This article will explore…

From Concept to Creation: Your Trusted Local Fabrication Shop

Click to Expand A reliable fabrication shop ensures precision and quality in its workmanship. It houses skilled technicians and state-of-the-art equipment, delivering products that meet exact specifications. Moreover, it adheres to rigorous quality control standards to guarantee consistency and reliability in every output. Such fabrication shop fosters trust and long-term partnerships by consistently providing exceptional…

The Heart of Central Valley: Discovering Local Metal Fabrication in Stockton

Click to Expand In the industrial landscape of California’s Central Valley, Stockton stands out as a vibrant hub of local metal fabrication. This versatile and essential manufacturing process involves shaping, cutting, and assembling metal materials to create various components and structures. It is employed across multiple industries, including construction, machinery, transportation, and more. At the…

Unveiling the Precision: ASME Code Work and Pressure Vessel Expertise

ASME code work encompasses activities that adhere to the American Society of Mechanical Engineers (ASME) standards. They include designing, fabricating, and inspecting engineering structures and components. One of its specific aspects involves pressure vessels. These are containers designed to hold gases or liquids at a pressure substantially different from the ambient pressure. Adhering to ASME…

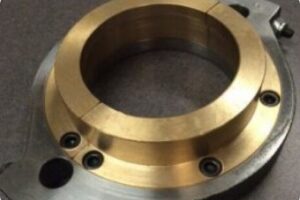

Crafting Excellence: The Art of Steel Fabrication at N.J. McCutchen, Inc.

Steel fabrication is the process of converting raw steel materials into predefined shapes, structures, or components through cutting, shaping, and assembling techniques. This involves skilled labor and specialized machinery to create products that meet design and engineering requirements. It is widely used in industries like construction, manufacturing, and infrastructure for creating diverse steel products from…