- Press brake bending: This uses a press brake machine to bend sheet metal into desired shapes. It is highly precise and suitable for producing straight bends, angles, and box-shaped components.

- Roll forming: This passes sheet metal through a series of rollers to gradually bend it into specific profiles. It is commonly used for producing long lengths of consistent, uniform shapes.

- Stretch forming: This stretches sheet metal over a die to achieve complex curves and outlines. It effectively produces curved or contoured sheet metal components with smooth surfaces.

Custom Sheet Metal Fabrication Master Guide

Importance of Customization in Sheet Metal Fabrication

Customization is pivotal in sheet metal fabrication for its ability to meet the unique specifications of individual projects. This guarantees that fabricated components fit into the intended application. Unlike off-the-shelf solutions, custom fabrication allows for precise adjustments in dimensions, shapes, and features, ensuring optimal functionality and performance.

Furthermore, customization enables companies to innovate and differentiate themselves in competitive markets. It also fosters flexibility, allowing manufacturers to adapt quickly to changing market trends or customer preferences. This agility can be a significant competitive advantage, helping them stay relevant in dynamic industries.

Lastly, customization enhances efficiency and cost-effectiveness in sheet metal fabrication processes. It reduces material waste, production time, and expenses by optimizing designs for manufacturability. In addition, customized components often require fewer modifications or adjustments during installation. This minimizes downtime and labor costs for assembly operators and ensures a seamless integration of the parts.

Techniques and Processes in Custom Sheet Metal Fabrication

Each of the following techniques in sheet metal fabrication serves specific purposes:

Cutting

Cutting is a manufacturing process that involves separating materials into desired shapes or sizes. It can be achieved through various methods, including the following:

- Shearing: This utilizes a shear blade to cut through sheet metal along a straight line. It is ideal for producing straight edges and simple shapes in sheet metal components.

- Laser cutting: This employs a high-powered laser to melt or burn material along desired paths. It is a preferred choice for industrial applications requiring high accuracy and efficiency.

- Waterjet cutting: This uses a high-pressure water stream mixed with abrasive particles to cut through various materials, including metals, plastics, ceramics, and composites.

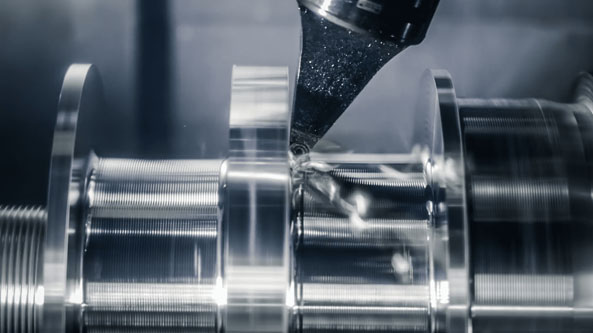

Bending and Forming

Bending deforms the metal along a straight line or curve, whereas forming encompasses a broader range of techniques to create complex shapes. Here are examples of bending and forming processes:

Joining and Assembly

Joining and assembly refer to the processes of connecting individual components or parts to create a unified structure or product. This can involve various methods, such as the following:

- Welding: This joins pieces by melting and fusing them together. It creates a strong and durable bond often essential for structural integrity in various applications.

- Riveting: This fastens metal components using rivets, which are inserted and deformed to create a permanent connection. It also allows for disassembly and repair.

- Adhesive bonding: This uses adhesives to bond metal parts together, offering lightweight and corrosion-resistant joints. It can accommodate irregular shapes and dissimilar materials.

Design Considerations in Custom Sheet Metal Fabrication

The following are important considerations when creating custom designs for sheet metal components:

Material Selection

Material choice greatly influences the performance and cost of sheet metal components. Factors such as strength, corrosion resistance, and formability must be carefully considered to ensure optimal longevity and functionality. Compatibility with fabrication processes and potential for recycling or sustainability may also impact material selection decisions.

Design for Manufacturability

Designing parts with manufacturability in mind streamlines the fabrication process and reduces costs. For example, features like uniform thickness, standard bend radii, and minimized technique complexity allow for efficient production and assembly. Furthermore, anticipating manufacturing constraints early in the design phase can prevent costly revisions.

Tolerances and Fit

Specifying acceptable tolerances ensures that sheet metal parts fit and function as intended. Moreover, understanding manufacturing process capabilities and accounting for dimensional variances are critical for attaining exact fit and alignment. Balancing tight tolerances with cost concerns can also avoid over-specification and excessive costs.

Structural Integrity

Structural integrity design involves optimizing part geometry to withstand anticipated loads and stresses. One way to achieve this is to incorporate features like stiffening ribs and filleted corners to enhance strength without adding excessive weight. Finite element analysis (FEA) and prototyping can also help validate designs and identify potential weak points before fabrication begins.

Surface Finish Requirements

Considering surface finish requirements ensures that fabricated components meet aesthetic and functional expectations. Factors such as texture, reflectivity, and paint adhesion may also influence surface treatment choices. Additionally, selecting appropriate finishing techniques early in the design process guarantees compatibility with material properties.

Quality Control and Inspection in Custom Sheet Metal Fabrication

Quality control and inspection are paramount in custom sheet metal fabrication to ensure that components meet rigorous standards and specifications. The process begins with planning and documenting quality requirements, such as dimensional tolerances, material properties, and surface finish criteria. This allows manufacturers to effectively monitor and evaluate each fabrication stage.

Continuous monitoring and inspection during fabrication help identify potential issues, which minimizes rework and scrap. This involves visual inspection, dimensional measurements, and non-destructive testing methods such as ultrasonic or magnetic particle testing. Implementing robust quality control protocols during this stage enhances product consistency and reliability.

Aside from in-process assessment, final inspection plays a role in verifying that fabricated components meet all specified requirements before delivery. This comprehensive evaluation thoroughly examines dimensions, surface finish, structural integrity, and functional performance. Any form of deviations or discrepancies detected are promptly addressed through corrective actions.

Quality control in custom sheet metal fabrication extends beyond individual components to include the entire production process. Continuous improvement initiatives — such as Six Sigma or lean manufacturing methodologies — are employed to optimize operations and enhance overall efficiency. This helps manufacturers deliver superior products and maintain a competitive edge in the marketplace.

Choose N.J. McCutchen, Inc. for High-Quality Fabrication Services

At N.J. McCutchen, Inc., we offer unparalleled expertise and service in sheet metal fabrication! We are located in Stockton, California, and our facility provides comprehensive, one-stop solutions for various projects. We also uphold the highest standards in steel fabrication, ensuring precision, durability, and reliability in every job we undertake.

Contact us or request a quote today!

Contact us