Materials that pose a risk to human or environmental health fall under the category of hazardous waste, which can also comprise inherently dangerous materials. Examples of these materials include toxic substances, harmful chemicals, radioactive materials, and other types of potential pollutants requiring safe disposal and handling. When determining how to safely and properly store and…

Best Practices for Machining Operations in Stockton

Safety and efficiency across machining operations are more important than ever. Setting best practices helps machinists more effectively leverage existing resources and meet precise design requirements. At N.J. McCutchen, we strive to help our clients maintain strong operations, product quality, and business security. That’s part of why we continue to refine our machining services in…

Choosing the Right Surface Preparation in Stockton: Sandblasting vs. Other Methods for Industrial Coatings

Before a metal component can be painted or powder coated, its surface must be free from dirt, oil, rust, and other contaminants that interfere with good adhesion. Sandblasting is a common choice, but there are many additional options available. Here, we’ll compare sandblasting with soda blasting, wet blasting, and vacuum blasting. We’ll also look at…

Understanding ASME Code Work

Companies that design, fabricate, and operate pressure vessels and related equipment need to understand ASME code work. The American Society of Mechanical Engineers (ASME) established this group of comprehensive codes and standards to ensure these processes happen safely, reliably, and efficiently. The ASME Boiler and Pressure Vessel Code (BPVC) was established in 1911. It remains…

The Heart of Central Valley: Discovering Local Metal Fabrication in Stockton

Click to Expand In the industrial landscape of California’s Central Valley, Stockton stands out as a vibrant hub of local metal fabrication. This versatile and essential manufacturing process involves shaping, cutting, and assembling metal materials to create various components and structures. It is employed across multiple industries, including construction, machinery, transportation, and more. At the…

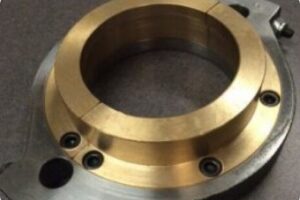

Unveiling the Precision: ASME Code Work and Pressure Vessel Expertise

ASME code work encompasses activities that adhere to the American Society of Mechanical Engineers (ASME) standards. They include designing, fabricating, and inspecting engineering structures and components. One of its specific aspects involves pressure vessels. These are containers designed to hold gases or liquids at a pressure substantially different from the ambient pressure. Adhering to ASME…

5 Reasons to Consider Sandblasting

Sandblasting is a method of using material at high pressure to clean surfaces. Common materials used for sandblasting include walnut shells, pumice and glass beads. You can choose more abrasive media to clean tougher jobs. Steel grit is a common option for blasting surface in preparation for paint. A professional sandblasting company will have the…

Fight Condensation to Protect the Painted Metal Surfaces in Industrial Facilities

All industrial facilities are different, however, there is one common thread in each facility – metal. Metal is a material that is widely used in industrial environments due to its increased versatility and durability. However, condensation is another commonality in these environments as large machinery often produces high amounts of heat, and condensation can be…

Secure Operations through Preemption: Maintaining Your ASME Pressure Vessel

Regardless of your specific industry, maintaining the highest safety standards in any industrial context is an extremely important part of guaranteeing productivity. Unfortunately, the most serious incidents tend to arise when equipment you’ve counted on suffers unexpected damage. When it comes to your pressure vessels, however, that damage can often times be anticipated and preempted….

Commercial Food Industry Equipment

The effectiveness of your food production facility is based on how great your equipment is. The type of food slicer, meat grinder, griddle, food dehydrator or stove that you will need is based on what you plan on cooking and how much you intend to cook. Durability The more frequently you will be using your…